Multiflex Installation and Maintenance Manual

Installation and Maintenance Video

Installation and Maintenance Manual

Index

1. MULTIFLEX VINYL FLOORING ROLL INSTALLATION

2. MULTIFLEX VINYL FLOORING ROLL MAINTENANCE

1. MULTIFLEX VINYL FLOORING ROLL INSTALLATION

1. Make sure the base is dry, clean, and free from deformation.

2. If you have an underfloor heating system, turn it off before starting the installation.

For safety reasons, we don’t recommend switching it on again.

3. Unroll the flooring and leave it in the room where it will be installed for 24 hours so it adapts to the room temperature and returns to its flat shape.

4. Before beginning, measure the area to be floored. Plan the installation carefully so you don’t waste material or end the rows with small portions of flooring.

5. Always leave a 10 mm space between the flooring and the wall or columns.

INSTALLATION

There are two possible systems for installing MultiFlex:

INSTALLATION WITH DOUBLE-SIDED TAPE

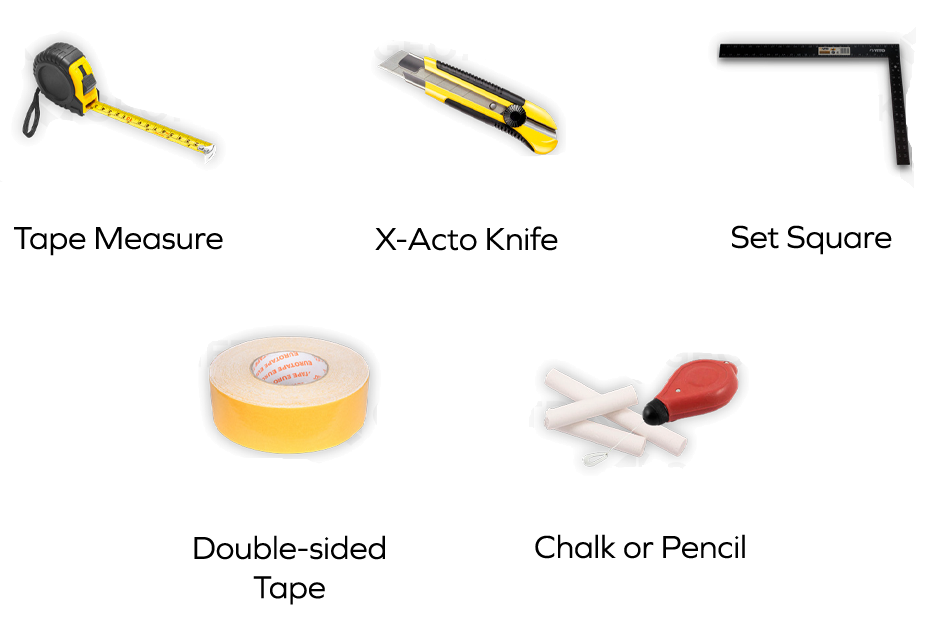

MATERIALS REQUIRED

INSTALLATION

1 – Using the X-Acto knife, set square and chalk, make all the required cuts before beginning the installation.

2 – Put the double-sided tape on the floor around the installation perimeter, creating a diamond. You’ll need 3 linear metres of double-sided tape for each square metre of MultiFlex.

3 – As the roll is installed on the adhesive tape, remove the top part of the tape so the roll sticks to the floor.

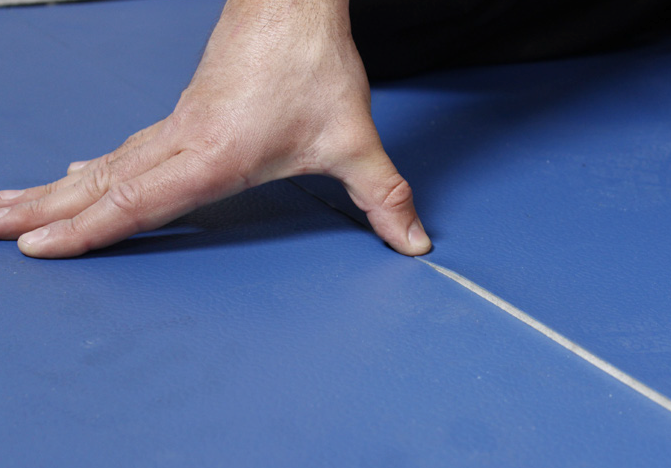

4 – Repeat this step for subsequent flooring rolls. Don’t forget to piece the ends together properly so the joints aren’t visible. Tip: to ensure the rollers are completely flush, overlay them slightly (about 1mm) and then force them together with a few small taps.

5 – Place heavy objects that don’t mark on the joints for 24 hours. This guarantees the flooring sticks to the adhesive tape.

INSTALLATION WITH GLUE

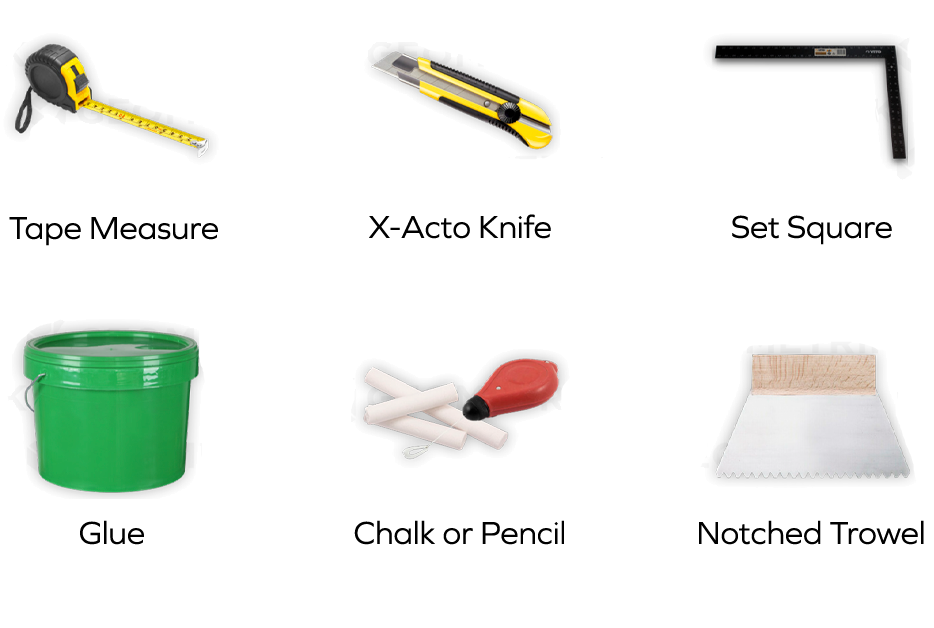

MATERIALS REQUIRED

GLUE PREPARATION

You need around 1kg of glue per m².

Glue has two components: resin and a catalyst. Mix them well and begin the installation immediately.

When ready, the glue can be used for 20 to 25 minutes. After, you can no longer use it for the installation.

Application should be done at a room temperature of between 15 and 25ºC and should never drop below 0ºC.

INSTALLATION

1 – Make all the required cuts before starting to install the flooring.

2 – Get the glue ready. Use a tool to manually mix the two glue components. Prepare small amounts of glue, as once ready, it must be used quickly.

3 – Use a notched trowel to spread the glue gradually, then place the MultiFlex on top.

4 – Repeat this step for subsequent flooring rolls. Don’t forget to piece the ends together properly so the joints aren’t visible. Tip: to ensure the rollers are completely flush, overlay them slightly (about 1mm) and then force them together with your hands.

5 – Then put objects that don’t mark on the joints for 24 hours to guarantee the flooring sticks to the glue.

2. MULTIFLEX VINYL FLOORING ROLL MAINTENANCE

Flooring maintenance and cleaning are essential to ensure a longer life.

If glue has been used to stick the flooring down, wait 3 days before cleaning with water to allow optimal glue adhesion.

Use a vacuum cleaner to regularly clean any rubbish from the surface. This prevents wear and tear/damage to the flooring.

For greater hygiene, use a microfibre mop (e.g. a yellow strip mop) together with pH-neutral detergents, which can be found in any supermarket.

Don’t use sponges, steel wool pads or bleach. These products may scratch and damage your flooring.

Note: The colour of the roll varies depending on the lighting and loses its brightness over time.